Add Time : 2019-08-31

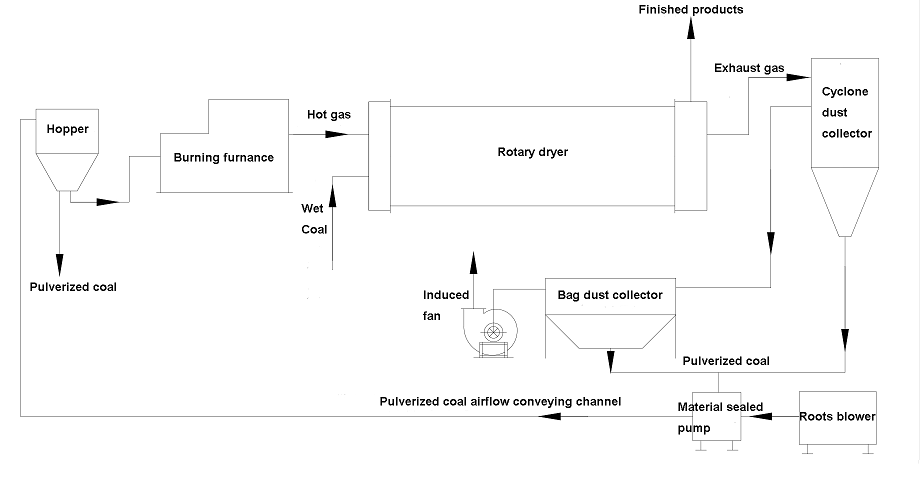

Coal Drying Flow Chart

Operation

Usually, pulverized coal put into hopper as fuel, transferred to burning furnace. The stream of hot gas produced from furnace mixed with the wet coal goes into the rotating cylinder.

Internal lifters or flights elevate the feed and drop it in a curtain from the top to the bottom cascading along the length of the dryer. Flights are carefully designed to prevent asymmetry of the curtain. Material moves from one end of the dryer to the other by the motion of the material falling due to the angle of inclination of the drum. Some rotary dryers are double and triple pass units where each drum is nested inside the previous drum.

Until reach the final moisture requirements detected by the PLC control system, fine coal is discharged, the exhaust gas which contains some coal powder goes into the cyclone dust collector. This process will get some pulverized coal, and which will be filtered by the bag dust collector.

The pulverized coal last will sent to hopper by belt conveyor, which is part of fuel of the whole production line.