Zhengzhou Dongding Machinery Co., Ltd.

Capacity: 300-2500 T/D

Power: 109-1200 kw

Final Moisture: ≤12%

Whatsapp: + 86 15736930209

Whatsapp: + 86 15736930209

Lignite generally has the disadvantages of high humidity (30%-50%), low ignition point and large carbon dioxide emissions. The direct combustion of the non-extraction lignite raw coal, will bring serious problems of environmental pollution, and increase the cost of plant installation. Besides, higher water content leads to transportation cost increasing.

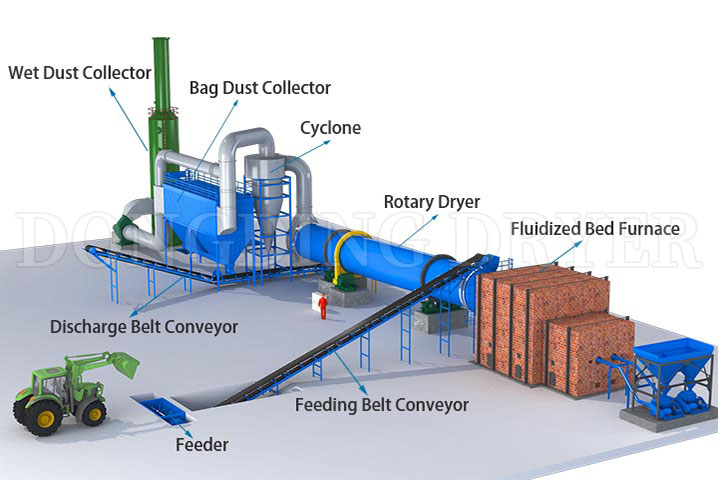

To solve the above problems of lignite properties, our company developed of a new lignite drying system. The lignite dryer adopts a new technology of crushing the lignite and then drying it by rotary dryer. That Makes the drying process realized continuous, industrialized and automated. The diameter of the drying drum of our company ranges from Φ1.9 meters to Φ3.4 meters, and the length ranges from 24 meters to 40 meters. And the processing capacity of lignite dryer is 300~2500T/D, the moisture content can be reduced from 40±5% to 10±2%; low calorific value of lignite can be increased by 1000-1800Kcal.

Firstly, the lignite is crushed by the crushing machine, transported to the screw conveyor by the belt conveyor, then go into the rotary drum, after drying, most of the dry material will be discharged through the belt conveyor, the left material will go into the cyclone dust collector, where the dust will be collected, with the function of induced draft fan, the left material will discharged through the conveyor.

1.Good drying effect, large process capacity

The hot fuel gas contact with the lignite directly , with sufficient heat exchange, good drying effect, large degree of dehydration one time, and high output.

2.The lignite will not get damp by absorbing water after drying

After drying, the lignite undergoes great physical and chemical changes, and the original loose structure is destroyed and reformed, and it will not absorb water , which is convenient for long-distance transportation.

3. Environmental protection and pollution-free. The lignite dryer system with low running noise. At the same time, it adopts clean thermal equipment and dust removal and desulfurization system to meet the customer's local environmental protection requirements;

4.High degree of automation and simple operation

The lignite rotary drum dryer adopts computer automatic control, which can realize remote control and easy operation. According to the drying requirements of our customers, different drying temperature and drying time can be configured to realize drying automation;

5.The lignite rotary drum dryer adopts the self-aligning tugboat structure, and the tugboat and rolling ring are well matched, which greatly reduces the wear and power consumption;

6.A variety of heat sources are available, such as: diesel, natural gas, rice husk, etc.

1.Fully technology support, free factory design and reasonable drying plant layout.

2.1 year guarantee.

3.100% carry out as contract.

4.We can send engineer to oversea to install at site.

5.Reasonable price and use good raw materials.

Specifications

|

Specification |

Capacity |

Initial Moisture |

Final Moisture |

Total Power |

Floor Area |

| DDMG1918 |

300±10 |

25±5 |

≤12 |

109 |

7m*25m |

|

DDMG2218 |

500±30 |

25±5 |

≤12 |

128 |

8m*30m |

|

DDMG2520 |

700±30 |

25±5 |

≤12 |

240 |

8m*30m |

|

DDMG2822 |

1000±30 |

25±5 |

≤12 |

400 |

8m*40m |

|

DDMG3024 |

1200±30 |

25±5 |

≤12 |

480 |

12m*50m |

|

DDMG3428 |

1500±30 |

25±5 |

≤12 |

600 |

12m*60m |

|

DDMG3830 |

1800±30 |

25±5 |

≤12 |

800 |

16m*70m |

|

DDMG4032 |

2000±30 |

25±5 |

≤12 |

1000 |

18m*70m |

|

DDMG4238 |

2500±30 |

25±5 |

≤12 |

1200 |

20m*80m |

Send Inquiry