Zhengzhou Dongding Machinery Co., Ltd.

Capacity: 300-2500 t/d

Power: 109-1200 kw

Final Moisture: ≤12%

Usage: Suitable for kinds of coal, raw coal, coal slag, coal slime, fly ash, lignite, anthracite, coal peat, coke, etc.

Whatsapp: + 86 15736930209

Whatsapp: + 86 15736930209

Coal Dryer Introduction

From mining to processing, there are many types of coal. They are usually have the problem of low calorific value, or unsuitable for transportation and storage. Thus, the drying is needed to upgrade the coal.

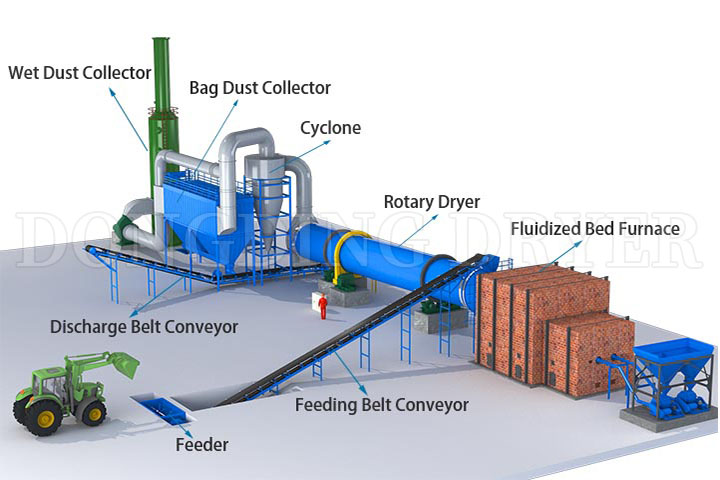

Our coal dryer system mainly consists of heating part (that can be designed accroding to the heating source you chose), feeding machine, rotary dryer, discharging machine and dust removal equipment, etc. This coal dryer system can be used for drying all types of coal, lignite, raw coal, carbon coal, anthracite, bituminous coal, lean coal and poor lean coal, etc, and the drying temperature, pressure, air volume, and rotating speed are strictly controlled according to different features of coal.

Besides, different types of lifting devices, cleaning devices, and crushing devices inside the drum dryer can solve the problem of walls sticking during the drying process.

Coal Dryer Drying Process Description

There are many lifting boards in the cylinder body. Through the rotation of the cylinder, lifting boards are driven to throw and spread the material continuously. Moreover, the crushing device of the cylinder wall breaks the material again. The lifted material is fully in contact with the hot air coming from the air induction system to exchange heat, evaporate water, and discharged from the outlet.

Coal Rotary Dryer Working Video

Coal Dryer Advantages

1. High evaporation efficiency

The hot flue gas and wet material enter the dryer from the same side by the downstream drying method. High evaporation efficiency can be obtained by using hot flue gas;

2. High efficiency

The coal drying system adopts a new feeding and discharging device, which eliminates the phenomenon of blockage, discontinuity, non-uniformity and refeeding of drum drier, and reduces the load of the dust removal system;

3. Wide adaptation to the moisture and viscosity of the material

The new internal structure strengthens the cleaning and heat conduction of the dispersed material, eliminates the phenomenon of sticking wall, and is more adaptable to the moisture and viscosity of the material;

4. Longlife service

The dryer adopts the "adjustable supporting roller device", so that the supporting roller and the rolling ring are always in linear contact, thereby greatly reducing wear and power loss;

5. Product size and moisture can be controlled according to user requirements

PLC control system can be used, after drying, the product moisture can reach below 8% and particle size can be controlled below 8mm;

6. Multiple fuel choice

coal, diesel, natural gas, waste wood, etc., can be used as heating source

What We Can Assure Our Clients?

1.Fully technology support, free factory design and reasonable drying plant layout.

2.100% carry out as contract.

3.We can send engineer to oversea to install at site.

4.Reasonable price and use good raw materials.

Rotary Drum Dryer in Factory

Rotary Drum Dryer Customer Visits

Coal Rotary Drum Dryer Cases

Specifications

|

Specification |

Capacity |

Initial Moisture |

Final Moisture |

Total Power |

Floor Area |

| DDMG1918 |

300±10 |

25±5 |

≤12 |

109 |

7m*25m |

|

DDMG2218 |

500±30 |

25±5 |

≤12 |

128 |

8m*30m |

|

DDMG2520 |

700±30 |

25±5 |

≤12 |

240 |

8m*30m |

|

DDMG2822 |

1000±30 |

25±5 |

≤12 |

400 |

8m*40m |

|

DDMG3024 |

1200±30 |

25±5 |

≤12 |

480 |

12m*50m |

|

DDMG3428 |

1500±30 |

25±5 |

≤12 |

600 |

12m*60m |

|

DDMG3830 |

1800±30 |

25±5 |

≤12 |

800 |

16m*70m |

|

DDMG4032 |

2000±30 |

25±5 |

≤12 |

1000 |

18m*70m |

|

DDMG4238 |

2500±30 |

25±5 |

≤12 |

1200 |

20m*80m |

Send Inquiry