Zhengzhou Dongding Machinery Co., Ltd.

Capacity: 300-2500 t/d

Material: FGD gypsum, phosphogypsum, sulfur gypsum, syn gyp, gypsum slag, gypsum sludge, kaolin, clay, etc.

Initial Moisture: 25±5%

Final Moisture: ≤5%

Total Power: 109-1200 Kw

Whatsapp: + 86 15736930209

Whatsapp: + 86 15736930209

Gypsum Dryer Introduction

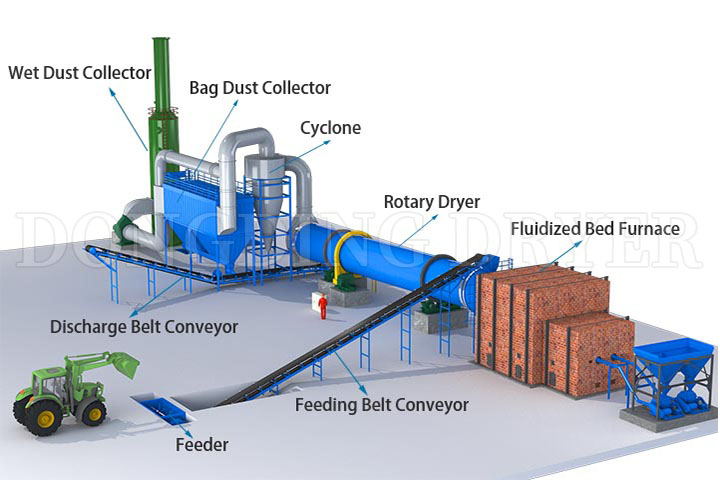

Gypsum dryers system of our company mainly consists of a heating machine, conveyor, feeding part, cylinder dryer, discharging part, and dust collector, etc. And the gypsum dryer system can be used to dry the FGD gypsum, phosphogypsum, sulfur gypsum, syn gypsum, gypsum slag, gypsum sludge and can be also used to dry Kaolin, clay, bentonite, etc.

After drying, the moisture of gypsum can be ≤7%, and the particle size can be controlled below 8mm. And dried gypsum can be used as cement additives in the cement manufacturing industry, and can be used in the wallboard manufacturing industry, etc. Gypsum dryer of our company is an environmental dryer with the features of reliable performance, low fault rate, stable operation, high efficiency and low electricity consumption.

Gypsum Dryer Working Process

The gypsum dryer is divided into the following working areas during the drying process:

1.In the material guiding working area, gypsum enters into the roller and fully contacts with the high temperature hot air here to evaporate water rapidly.

2.The cleaning area; The cleaning device and crushing device in the cleaning area can effectively clean and crush the materials sticking to the inner wall, thus increasing the heat exchange area and improving the drying efficiency.

3.Inclined material lifting area; where the gypsum has a low moisture and loose state, and after full heat exchange, it reaches the required moisture.

4.The discharging area; where the material rolls and slides to the discharge port to complete the whole drying process.

Gypsum Rotary Dryer Running Video

Importance of Drying Gypsum

1. Drying gypsum hardens the material and avoids congesting equipment in future steps,such as grinding;

2. The drying process prevents the matrial from some handling issues such as clumping. Drying also forms a strong pellet that is capable of breaking down quickly;

3. The tumbling action within the gypsum dryer rounds and polishes the pellet, helps to create a uniform, premium product.

Our Gypsum Dryer Features

1. The gypsum dryer adopts the downstream drying technology, the flue gas and materials enter into the drum at the same side, with high thermal efficiency;

2. The gypsum dryer has the advantages of stable operation, strong processing capacity, low fuel consumption and low drying cost;

3. The new internal structure is adopted to strengthen the cleaning of materials and reduce the phenomenon of gypsum sticking to the wall;

4. According to the requirements of customers, the product size and moisture can be controlled. After drying, the moisture of gypsum can be ≤7%, and the particle size can be controlled below 8mm.

Rotary Drum Dryer in Factory

Customer Visit

Rotary Drum Dryer Cases

Specifications

|

Specification |

Capacity |

Initial Moisture |

Final Moisture |

Total Power |

Floor Area |

| DDMG1918 |

300±10 |

25±5 |

≤5 |

109 |

7m*25m |

|

DDMG2218 |

500±30 |

25±5 |

≤5 |

128 |

8m*30m |

|

DDMG2520 |

700±30 |

25±5 |

≤5 |

240 |

8m*30m |

|

DDMG2822 |

1000±30 |

25±5 |

≤5 |

400 |

8m*40m |

|

DDMG3024 |

1200±30 |

25±5 |

≤5 |

480 |

12m*50m |

|

DDMG3428 |

1500±30 |

25±5 |

≤5 |

600 |

12m*60m |

|

DDMG3830 |

1800±30 |

25±5 |

≤5 |

800 |

16m*70m |

|

DDMG4032 |

2000±30 |

25±5 |

≤5 |

1000 |

18m*70m |

|

DDMG4238 |

2500±30 |

25±5 |

≤5 |

1200 |

20m*80m |

Send Inquiry