Zhengzhou Dongding Machinery Co., Ltd.

Capacity: 300-2500 T/D

Initial Moisture: 15±5%

Final Moisture: ≤8%

Total Power: 109-1200 Kw

Whatsapp: + 86 15736930209

Whatsapp: + 86 15736930209

Bentonite Dryer Introduction

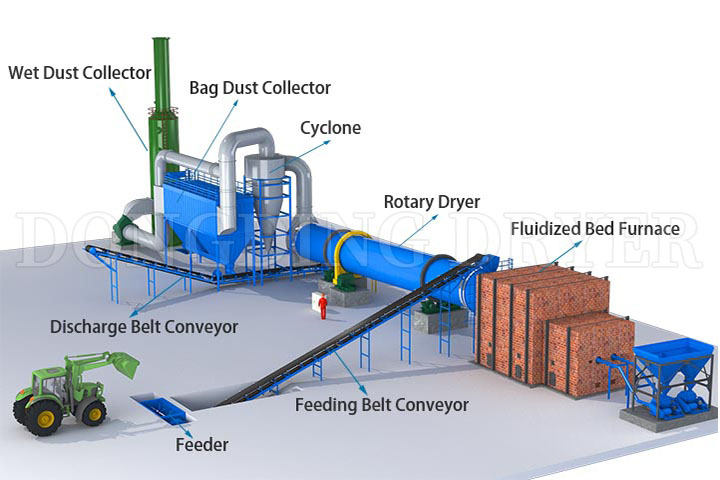

The mined bentonite is usually with a moisture content between 25 and 35% and required to be dried to 5% to 12% for further use. Bentonite dryers system of our company mainly consists of a heating machine, conveyor, feeding part, cylinder dryer, discharging part, and dust collector, etc. It is specially designed to dry the wet bentonite to the dried bentonite with moisture content less than 7%. Different types of lifting devices, cleaning devices, and crushing devices that specially designed inside the drum dryer can solve the problem of walls sticking. And after drying, the particle size can be controlled below 8mm. It is widely used in building materials, metallurgy, chemical, and cement industries to dry bentonite materials.

Raw Material

Calcium bentonite

Sodium bentonite

Potassium bentonite

Kaolin

Bentonite clay

Ball clay

Fire clay

Fuller’s earth (Input moisture: 40-50%, final Moisture: 10%)

Bentonite Dryer System

Rotary Dryer Running Video

Advantages

1. The bentonite dryer has the advantage of large processing capacity, low fuel consumption and low drying cost;

2. Bentonite dryer has the characteristics of high temperature resistance, which can use high temperature hot air to dry materials quickly;

3.The bentonite dryer adopts computer automatic control, which can realize remote control and easy operation. According to the drying requirements of bentonite, different drying temperature and drying time can be configured to realize drying automation;

4. The bentonite dryer adopts the self-aligning tugboat structure, and the tugboat and rolling ring are well matched, which greatly reduces the wear and power consumption;

5.The specially designed block wheel structure greatly reduces the horizontal thrust caused by the tilt of the equipment;

6. A variety of heat sources are available, such as: diesel, natural gas, rice husk,etc.

Rotary Drum Dryer in Factory

Custom Visit

Rotary Drum Dryer Cases

Specifications

Bentonite Dryer Technical Paramete

|

Specification |

Capacity |

Initial Moisture |

Final Moisture |

Total Power |

Floor Area |

| DDMG1918 |

300±10 |

15±5 |

≤8 |

109 |

7m*25m |

|

DDMG2218 |

500±30 |

15±5 |

≤8 |

128 |

8m*30m |

|

DDMG2520 |

700±30 |

15±5 |

≤8 |

240 |

8m*30m |

|

DDMG2822 |

1000±30 |

15±5 |

≤8 |

400 |

8m*40m |

|

DDMG3024 |

1200±30 |

15±5 |

≤8 |

480 |

12m*50m |

|

DDMG3428 |

1500±30 |

15±5 |

≤8 |

600 |

12m*60m |

|

DDMG3830 |

1800±30 |

15±5 |

≤8 |

800 |

16m*70m |

|

DDMG4032 |

2000±30 |

15±5 |

≤8 |

1000 |

18m*70m |

|

DDMG4238 |

2500±30 |

15±5 |

≤8 |

1200 |

20m*80m |

Send Inquiry