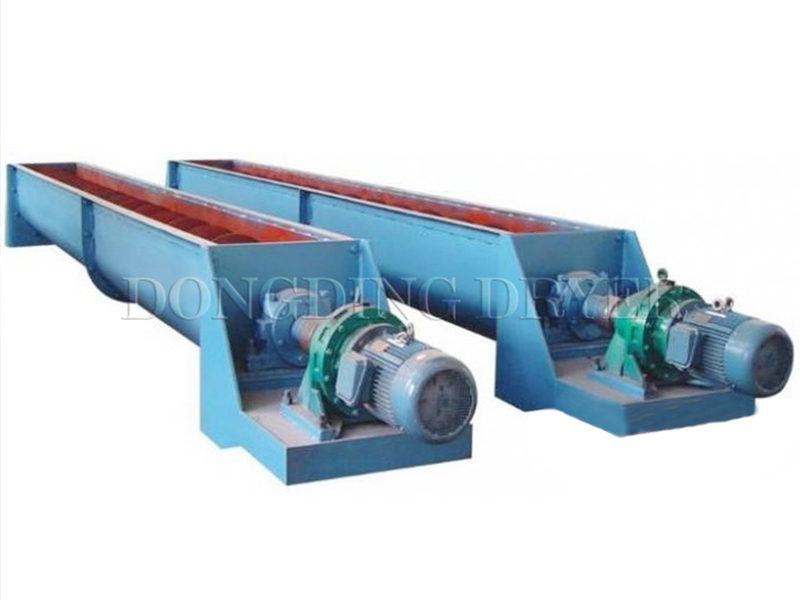

Screw Conveyor Introduction

Screw conveyors are used to convey materials such as bulk solids or sludge both on horizontal and high inclination, and screw conveyors are designed to provide an enclosed method of transferring materials from one point to another. It consists of a screw inside a hollow pipe, screw conveyors contained within a tube and it is turned with the help of a motor in order to deliver material from one end of the screw conveyors to the other.

Screw Conveyors Bucket Elevators equipment play an important role in transporting material from one mill to another. Some Screw Conveyors are designed to operate horizontally, some on a slope, others bucket elevators elevate the material vertically to a different level of the building. The requirement for bucket elevator conveyors will depend on how automated the mill is to be and how its plant is laid out.

The frequent use of screw conveyors and bucket elevators is made in the modern pellet mill (often using pneumatic systems) to minimize labour needs maximise the use of land by building multi-storey, rather than horizontally arranged plants.

Screw Conveyor Features

♦ It is with simple structure, small cross sectional dimension, good sealing performance, low cost and easy operation.

♦ It is convenient to feed and discharge during operation, and the conveying direction can be opposite.

♦ Materials can be mixed, agitated, heated and cooled during conveying.

♦ Material flow can be adjusted by loading/unloading value.

Whatsapp: + 86 15736930209

Whatsapp: + 86 15736930209