Zhengzhou Dongding Machinery Co., Ltd.

Capacity: 300-2500 T/D

Final Moisture: 12-15%

Total Power: 109-1200 Kw

Floor Coverage: 175-1600 m2

Whatsapp: + 86 15736930209

Whatsapp: + 86 15736930209

Coal Slime Rotary Dryer Introduction

Coal slime has high water content, large viscosity, small particles, not easy to transport, its economic value is low, very unstable, easy to weathering, According to these characteristics, Dongding has developed a special coal slime dryer, strictly control the drying temperature of the dryer, pressure, air volume and speed. Besides, it also equipped with different forms of feeding device, cleaning device, crushing device, fully realizing heat exchange and thermal transformation, improoving the drying efficiency and heat utilization rate, and reducing the emission of exhaust dust, which is energy saving and environmental protection.

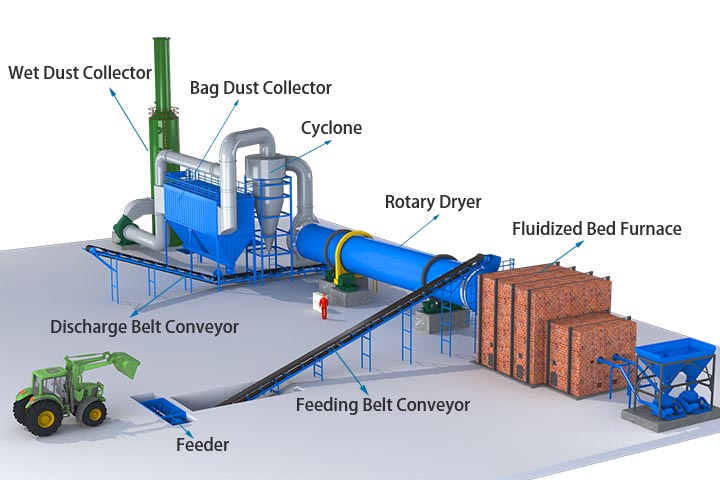

Coal Slime Rotary Dryer Working Principle

Firstly, wet material is crushed by the crushing machine, then transported to the rotary drum dryer by the belt conveyor. Because of the inclination of drum dryer, material with hot air moves to the end of dryer body, during which process wet material gets fully contact with the hot air. After drying, most of the dry material is discharged through the belt conveyor. The left material mixed with dust continue goes into the cyclone dust collector and the bag dust collector in sequence, where the dust will be collected. Lastly, with the function of induced draft fan, the left material will discharged through the conveyor.

Coal Slime Rotary Dryer Running Site

Coal Slime Rotary Dryer Features

1. Customized Solution. According to the properties of different coal slurry to change the operating parameters.

2. Special internal structure, eliminating the adhesion phenomenon of the inner wall.

3. Multiple Heating Source. Customers can choose the heating source according their situation, we can design the customized solutions.

4. Designed Inner Structure For Sawdust Material. High drying efficiency to 90-95%.

5. The system is equipped with PLC system and video monitoring system, with a high degree of automation and simple operation.

6. HighThe system has a unique sealing structure, no thermal energy leakage.

7. Low investment, low operating cost, and short investment recovery time.

8. Provide Accessory Parts. Accessory parts quality assured.

Rotary Drum Dryer in Factory

Coal Rotary Drum Dryer Cases

More Coal Slime Drying Site for Reference:

Mongolia 2100T/D coal Drying Project

Shanxi 1200T/D Coal Drying Plant

Yangta 1000 T/D Coal Dryer Project

Shenyuan 1000 T/D Coal Slime Drying Project

Specifications

|

Specification |

Capacity |

Initial Moisture |

Final Moisture |

Total Power |

Floor Area |

| DDMG1918 |

300±10 |

25±5 |

≤12 |

109 |

7m*25m |

|

DDMG2218 |

500±30 |

25±5 |

≤12 |

128 |

8m*30m |

|

DDMG2520 |

700±30 |

25±5 |

≤12 |

240 |

8m*30m |

|

DDMG2822 |

1000±30 |

25±5 |

≤12 |

400 |

8m*40m |

|

DDMG3024 |

1200±30 |

25±5 |

≤12 |

480 |

12m*50m |

|

DDMG3428 |

1500±30 |

25±5 |

≤12 |

600 |

12m*60m |

|

DDMG3830 |

1800±30 |

25±5 |

≤12 |

800 |

16m*70m |

|

DDMG4032 |

2000±30 |

25±5 |

≤12 |

1000 |

18m*70m |

|

DDMG4238 |

2500±30 |

25±5 |

≤12 |

1200 |

20m*80m |

Send Inquiry