Zhengzhou Dongding Machinery Co., Ltd.

Capacity: 30-480 t/h

Power: 90-1300 kw

Final Moisture: <9%

Whatsapp: + 86 15736930209

Whatsapp: + 86 15736930209

Advanced Dry Coal Preparation Introduction

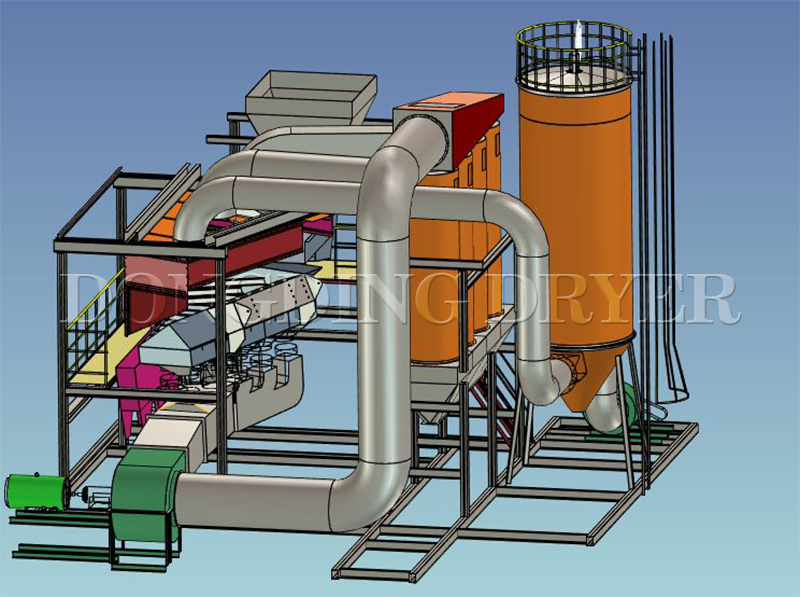

The compound dry coal preparation equipment is a new type of coal extraction equipment developed by Dongding, which has a series of advantages, such as no water use, simple process, less investment, low production cost, high recovery rate, low energy consumption, no pollution to the environment, low equipment accident rate and short construction cycle. Composite Dry Coal Preparation is welcomed by coal mines, coal transportation stations, coking plants, gas plants, coal preparation plants and other enterprises. Dongding Composite dry coal preparation technology fully meets the national protection of water resources, energy conservation, environmental protection and coal deep processing and a series of policies, has broad application prospects.

Working Principle

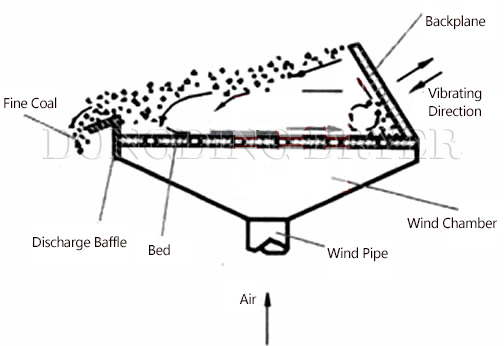

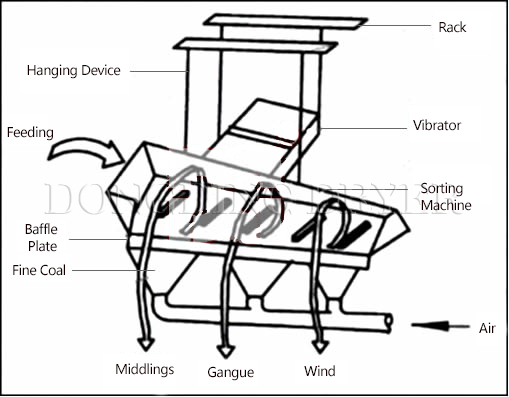

The selected material is sent from the feeder to the feeding port of the sorting bed, and a bed layer with a certain thickness is formed on the bed surface. The lowest level of material is directly in contact with the vibrating bed surface, the inertial force generated by the vibration of the bed surface makes the lower material from the discharge bezel move to dorsal plate. Because of the back plate, the material moves upward. The upper material is affected by the gravity, slipping along the surface to the discharge edge. The lowest layer density of coal is first discharged through the discharge bezel, the rest of the material continue to do the next cycle movement. Due to the vibration force and continuous entry into the sorting bed material pressure, the continuous flip of the material form an approximate spiral movement, and move to the end of the gangue. Due to the gradual reduction of the bed width, the upper density of relatively low coal is constantly discharged, until the final discharge of large density of gangue and pyrite. On the one hand, the function of wind strengthens to loose the granularity group, on the other hand, it is composed of gas-solid two-phase mixed medium with fine coal, which improves the sorting accuracy.

Equipment Composition:

The composite dry separator is composed of sorting bed, vibrator, wind chamber, rack and hanging device. The sorting bed consists of a bed surface, a backplane, a lattice bar and a discharge baffle. There is a wind chamber under the bed that can control the air volume, which is supplied by the centrifugal ventilator, and the airflow acts on the sorting material through the wind hole on the bed surface. The separation bed and vibrator are suspended on the rack by the hanging device, and the longitudinal and transverse angles of the sorting bed can be adjusted arbitrarily.

Features

1. Unique working principle, high sorting precision, large processing capacity;

2. Coal selection does not use water, the process is simple;

3. Achieve fully enclosed operation, environmental protection and efficiency;

4. Low production costs and low operating costs;

5. After the selection, low coal moisture, high heating volume, high recovery rate;

6. Smooth operation, small maintenance capacity;

7. Low investment and short construction cycle.

Product Details

Specifications

|

Model |

Capacity |

Granularity |

Final Moisture |

Total Power |

Floor Area |

| DDFGX-3 |

30 |

3 |

<9 |

92 |

9.8×8.6×8.8 |

|

DDFGX-6 |

60 |

6 |

<9 |

146 |

12×11×10

|

|

DDFGX-9 |

90 |

9 |

<9 |

277 |

|

Add: No. 345, Huaxia Road, Airport Economy Zone, Zhengzhou, China