Zhengzhou Dongding Machinery Co., Ltd.

Capacity: 200-1000 t/d

Application: lignite, thermal coal, coking coal, raw coal, bituminous coal,anthracite, etc

Whatsapp: + 86 15736930209

Whatsapp: + 86 15736930209

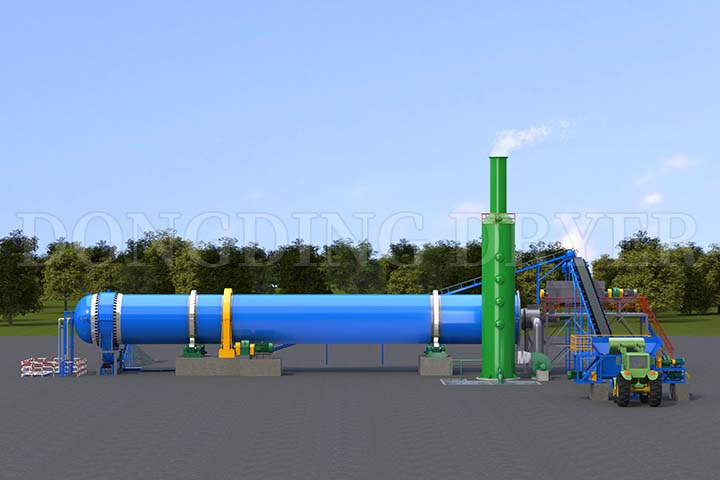

Steam Tube Dryer for Coal Introduction

Steam tube dryer for coal adopts indirect drying method. It can use low pressure steam such as extract steam from turbine to dry kinds of low rank coal. Steam tube dryer can be used to dry lignite, thermal coal, coking coal, raw coal, bituminous coal,anthracite, etc. At present, coal steam tube dryer is widely used in power plants, gasification plants, etc.

Coal Steam Tube Dryer Process Description

The wet material enters the steam tube dryer through the dispersing feeder, belt conveyor, and screw conveyor. With the rotation of the drum, wet material contacts the steam tube inside the dryer for heat exchange to be dried, and gradually moves to the discharge end. The dried material is discharged out of the dryer. The moisture evaporated from the wet material is carried out by the wet gas, then discharged by the induced draft fan after being purified by water bath dust collector.

Coal Steam Tube Dryer Advantages

1. Environmental friendly

No flue gas is generated during the drying process, and desulfurization and denitrification are not required; the dust removal adopts bag type or electric dust removal, without generating wastewater.

2. Safe operation

The heat source is low-pressure steam, with a pressure not less than 0.4Mpa and a temperature not exceeding 300 ℃. The heat exchange method is indirect heat exchange. During the drying process, no air enters the inside of the dryer, and basically no dust is carried. This not only reduces energy consumption, but also reduces the internal temperature, oxygen content, and concentration inner the dryer. Compared to traditional flue gas coal drying, the operational safety is greatly improved.

3.Energy Saving

One is to use steam heat source for indirect heat exchange, and the heat transfer mechanism is heat conduction; the other is to use dehumidification process, which has less air volume, lower fan power and the condensed water after steam heat exchange can be recycled.

What We Can Assure Our Clients?

1.Fully technology support, free factory design and reasonable drying plant layout;

2.1 year guarantee;

3.100% carry out as contract;

4.We can send engineer to oversea to install at site;

5.Reasonable price and use good raw materials.

Specifications

|

Models |

Rotary Drum Size (mm) |

Heat Transfer Area (㎡) |

|

DDZHG-200 |

φ1600 |

200 |

|

DDZHG-300 |

φ2000 |

300 |

|

DDZHG-460 |

φ2440 |

460 |

|

DDZHG-560 |

φ2440 |

560 |

|

DDZHG-640 |

φ2440 |

640 |

|

DDZHG-720 |

φ3000 |

720 |

|

DDZHG-850 |

φ3200 |

850 |

|

DDZHG-950 |

φ3400 |

950 |

|

DDZHG-1100 |

φ3600 |

1100 |

|

DDZHG-1200 |

φ3800 |

1200 |

Send Inquiry