Zhengzhou Dongding Machinery Co., Ltd.

Capacity: 10-70 t/h

Final Moisture: ≤1%

Application: river sand, silica sand, dry mortar, yellow sand, slag of cement plant, etc.

Whatsapp: + 86 15736930209

Whatsapp: + 86 15736930209

Sand Rotary Dryer Introduction

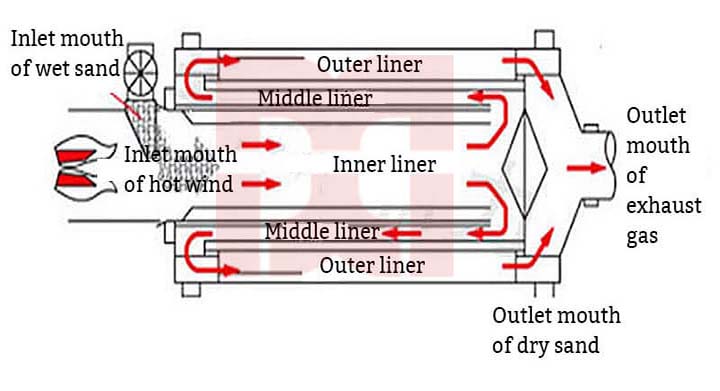

Sand dryer, also known as the three layers of drum dryer, three return cylinder dryer, is designed and manufactured by our company on the basis of the single cylinder dryer by adopting the latest European energy-saving technology: mosaic structure.

Sand dryer is widely used for drying bulk and powder materials below 20mm. It can dry river sand, silica sand, dry mortar, yellow sand, slag of cement plant, etc. It is widely used in building materials, chemical industry, foundry and other industries. The heating source can be coal, oil and gas, etc.

Sand Rotary Dryer Working Principle

The raw material, sand, is conveyed to the inner cylinder by the feeder continuously and evenly , and is thrown and pushed forward by the spiral lifting board. In addition, it is dispersed by the intermediate dispersing device to form a curtain which fully contacts with the heat. The water evaporates rapidly then led out induced draft fan. Semi-dry material enters the middle cylinder and outer cylinder, and then fully contacts with the heat finally enters the discharge bin after meeting the final drying requirements.

Sand Rotary Dryer Running Video

Why Choose Our Sand Rotary Dryer

1. Long Time Service

It is made of wear-resistant manganese plate, which is more wear-resistant than ordinary steel plate;

2. Good Output Effect

The initial moisture of the material is about 15%, and the final moisture after drying is ensured to be below 0.5-1%.

It is the first choice for various drying projects such as slag powder in cement plant cement plant, GGBS and dry mortar production line;

3. Less cosumption and High Efficiency

Compared with the traditional single pass rotary dryer, the thermal efficiency of the sand dryer is increased by more than 40%; coal consumption of the sand dryer is one third of that of the single pass rotary dryer, saving 20% of the electricity, and the consumption of the standard coal per ton is less than 9kg for drying one tons of the material.

4. Investment Cost Saving

The sand dryer saves about 60% floor area than single pass rotary dryer; The investment in civil construction is reduced by about 60%, and the installation is more convenient;

5. No Air Leakage, High Efficiency

There is no air leakage, thus the sealing difficulty is completely solved;

6. Simple Process

The discharge temperature is less than 60 degrees, and it can be directly fed into the material warehouse without the cooling process.

Specifications

|

Model |

DDSΦ2.0×4.5m |

DDS Φ2.0×5.4m |

DDS Φ3.2×6.4m |

DDSΦ3.6×8m |

|

Outer Drum Diameter (m) |

2.0 |

2.5 |

3.2 |

3.6 |

|

Outer Drum Length (m) |

4.5 |

5.4 |

6.4 |

8 |

|

Drum Volume (m³) |

14.1 |

16.63 |

52.7 |

81.38 |

|

Drum Rotation (rpm) |

4-10 |

4-10 |

4-10 |

4-10 |

|

Sand Initial Moisture (%) |

8-10 |

8-10 |

8-10 |

8-10 |

|

Sand Final moisture (%) |

0.5-1 |

0.5-1 |

0.5-1 |

0.5-1 |

|

Inlet Air Temperature (℃) |

700-750℃ |

700-750℃ |

700-750℃ |

700-750℃ |

|

Capacity (t/h) |

13-17 |

21-28 |

45-47.5 |

65-70 |

|

Motor Model |

Y2-132m-4E |

Y2-132m-4E |

Y2-160m-4E |

Y2-160m-4E |

|

Motor Power kW |

5.5×2 |

5.5×4 |

7.5×4 |

11×4 |

|

Reducer Model |

XWD-5-5.5kW-5 |

XWD-5-5.5kW-5 |

XWD-7.5kW-8 |

XWD-11kW-8 |

|

Reducer Ratio 1 |

29 |

29 |

29 |

29 |

Send Inquiry