Zhengzhou Dongding Machinery Co., Ltd.

Capacity: 300-2500 T/D

Initial Moisture:≤30%

Final Moisture: ≤3%

Whatsapp: + 86 15736930209

Whatsapp: + 86 15736930209

Slag Rotary Dryer Introduction

Slag, also known as molten slag, is the industrial waste produced in steelmaking process. Slag has a wide application, such as replacing natural gravel as concrete aggregate, roadbed, foundation cushion, etc., and it can also be made into cement, glass, bricks, or be used to make agricultural fertilizers, etc.

The slag needs to be dried before it can be used. Our slag dryer is designed according to the features of the slag, with the advantages of large processing capacity and high efficiency.

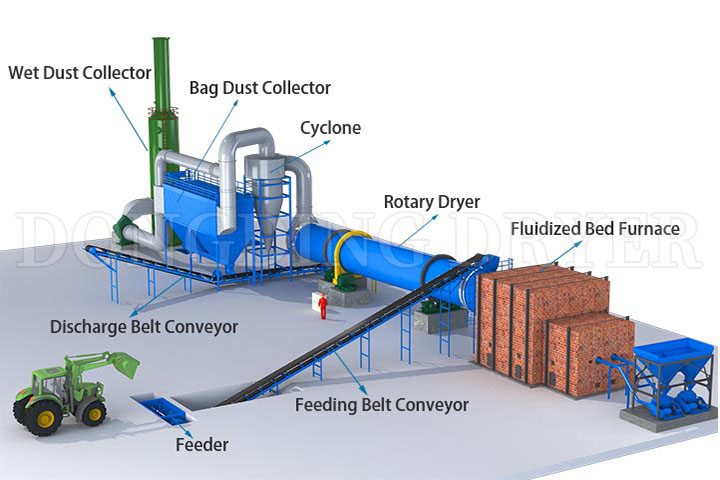

Slag Rotary Dryer System

The whole sludge rotary drying system consists of the feeder, rotary drum dryer, discharging machine, induced draft fan, cyclone dust collector and distribution cabinet, etc.

Slag Rotary Dryer Working Principle

The wet slags is sent to the dryer drum together with the hot air.A special dispersing device is installed inside the dryer to ensure that wet slag continuously disperse, separate and accelerate the contact with the high-temperature hot air inside the dryer, which can not only prevent the slag from caking, but can also quickly reduce the moisture content of the slag. The dried slag is discharged through the discharge port, while the slag materials that have not been dried will continue to be dried.

Why Choose Our Slag Dryer

1.High drying efficiency

The main parts of the slag dryer are made of high-quality wear-resistant materials with high temperature resistance and stability, which can reduce heat loss and improve drying efficiency by more than 60%;

2.Good drying performance

The specially designed lifting plates with multiple shapes are installed on the inner wall of the slag dryer barrel to increase the contact surface between the material and the hot airflow, thereby bringing more working efficiency and higher drying performance.

3.Safe and reliable operation

The cylinder of slag dryer is sealed well, without heat and dust leakage, thus ensure the safe and reliable operation.

Slag Rotary Dryer in Factory

Customer Visits

Rotary Dryer Cases

Specifications

Specification | Capacity | Initial Moisture | Final Moisture | Total Power | Floor Area |

| DDMG1918 | 300±10 | 25±5 | ≤3 | 109 | 7m*25m |

DDMG2218 | 500±30 | 25±5 | ≤3 | 128 | 8m*30m |

DDMG2520 | 700±30 | 25±5 | ≤3 | 240 | 8m*30m |

DDMG2822 | 1000±30 | 25±5 | ≤3 | 400 | 8m*40m |

DDMG3024 | 1200±30 | 25±5 | ≤3 | 480 | 12m*50m |

DDMG3428 | 1500±30 | 25±5 | ≤3 | 600 | 12m*60m |

DDMG3830 | 1800±30 | 25±5 | ≤3 | 800 | 16m*70m |

DDMG4032 | 2000±30 | 25±5 | ≤3 | 1000 | 18m*70m |

DDMG4238 | 2500±30 | 25±5 | ≤3 | 1200 | 20m*80m |

Send Inquiry