Zhengzhou Dongding Machinery Co., Ltd.

Capacity: 300-2500 T/D

Initial Moisture:≤30%

Final Moisture: ≤8%

Whatsapp: + 86 15736930209

Whatsapp: + 86 15736930209

Sludge Rotary Dryer Introduction

Dongding Sludge Rotary Drying System is suitable for drying various kinds of sludge with high viscosity. The sludge with moisture of about 85% can be dehydrated and dried into dry powder with moisture less than 10%. After dried, sludge weight will reduce by approximately 60%; and the volume of sludge will reduce by 4-5 times. Thus, the transportation cost of sludge will reduce significantly. Also, environmental problems associated with sludge will reduce substantially.

And sludge dryer design varies from the unique characteristics of the sludge to be processed. The retention time, length and diameter, air flow configuration (co-current or counter-current flow), are specially designed according to characteristics of the raw material; and when it comes to sticky materials, different types of lifting devices, cleaning devices, and crushing devices inside the dryer can solve the problem of walls sticking during the drying process. And the main body of the drum can be made of carbon steel or stainless steel to meet the special needs.

Sludge Rotary Dryer Casted by Stainless Steel

Application & Materials

The sludge dryer system can be applied to the drying of activated sludge, sewage sludge, petrochemical sludge, papermaking sludge, printing and dyeing sludge, tanning sludge, electroplating sludge, municipal sludge, biological fermentation sludge, etc. In addition, it is also applied to coal sludge drying, coal slurry drying, etc. The dried product produced out of drying sludge can be used as fertilizer, biofuel, etc.

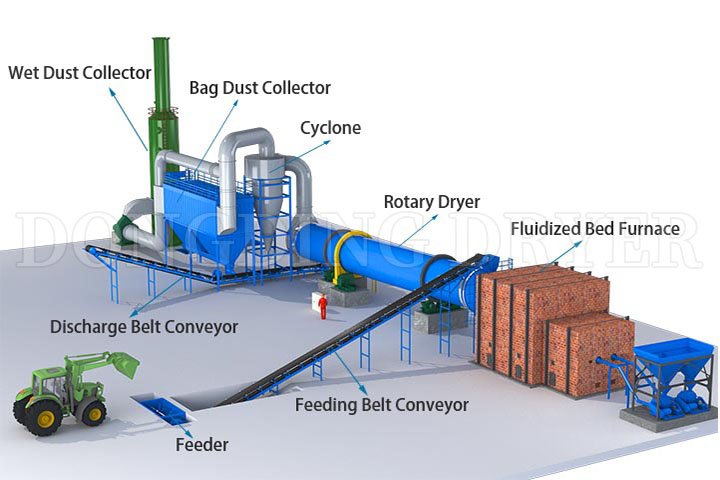

Sludge Rotary Dryer System

The whole sludge rotary drying system consists of the dehydrator machine (if needed), feeder, sludge rotary drum dryer, discharging machine, induced draft fan, cyclone dust collector and distribution cabinet, etc.

Sludge Rotary Dryer Working Principle

Firstly, high moisture sludge is dewatered by the dewatering machine, then transported to the rotary drum dryer by the belt conveyor,where it will fully contact with the hot air. with the running of drum dryer, material with hot air moves to the end of dryer body.

After drying, most of the dry material will be discharged through the belt conveyor, the left material will go into the cyclone dust collector, where the dust will be collected, then discharged through the conveyor.

Sludge Rotary Dryer Site

Why Choose Our Sludge Dryer

1. Custom engineered inter structure according the features of raw material;

2. Specially designed lifting flights to maximize heat transfer between the material and hot gas stream;

3. High temperature resistance, which can use high temperature hot air to dry materials quickly;

4. The sludge dryer adopts computer automatic control, which can realize remote control and easy operation. According to needs, different drying temperature and drying time can be configured to realize drying automation;

5. The sludge dryer adopts the self-aligning tugboat structure, and the tugboat and rolling ring are well matched, which greatly reduces the wear and power consumption;

6. The specially designed block wheel structure greatly reduces the horizontal thrust caused by the tilt of the equipment;

7. Multiple heating source; sludge rotary drying system can use the boiler exhaust gas as the heat source of the rotary dryer, which greatly reduces the cost and has no secondary pollution. In addition, the heating source can be biomass pellets, electricity, fossile fuel, coal, etc.

Sludge Rotary Dryer in Factory

Customer Visits

Sludge Rotary Dryer Cases

Specifications

|

Specification |

Capacity |

Initial Moisture |

Final Moisture |

Total Power |

Floor Area |

| DDMG1918 |

300±10 |

25±5 |

≤8 |

109 |

7m*25m |

|

DDMG2218 |

500±30 |

25±5 |

≤8 |

128 |

8m*30m |

|

DDMG2520 |

700±30 |

25±5 |

≤8 |

240 |

8m*30m |

|

DDMG2822 |

1000±30 |

25±5 |

≤8 |

400 |

8m*40m |

|

DDMG3024 |

1200±30 |

25±5 |

≤8 |

480 |

12m*50m |

|

DDMG3428 |

1500±30 |

25±5 |

≤8 |

600 |

12m*60m |

|

DDMG3830 |

1800±30 |

25±5 |

≤8 |

800 |

16m*70m |

|

DDMG4032 |

2000±30 |

25±5 |

≤8 |

1000 |

18m*70m |

|

DDMG4238 |

2500±30 |

25±5 |

≤8 |

1200 |

20m*80m |

Send Inquiry