Zhengzhou Dongding Machinery Co., Ltd.

Capacity: 3-20 T/H

Initial Moisture: 20±5

Final Moisture: ≤5

Application: clay, bentonite, kaolin, coal slag, limestone, bauxite, river sand, etc.

Whatsapp: + 86 15736930209

Whatsapp: + 86 15736930209

Clay Rotary Dryer Introduction

Clay is a kind of natural mineral material with excellent performance. It is widely used in metallurgy, chemical industry, cosmetics, steel, petroleum and other fields. However, the clay contains a certain amount of water, which requires proper drying to achieve better industrial value. Our clay dryer machine is a kind of rotary drum dryer specially designed for clay drying. The moisture content of dried clay can be less than 5%.

And different types of lifting devices, cleaning devices, and crushing devices that specially designed inside the drum dryer can solve the problem of walls sticking. After drying, the particle size can be controlled below 8mm. It is widely used in building materials, metallurgy, chemical, and cement industries to dry bentonite materials.

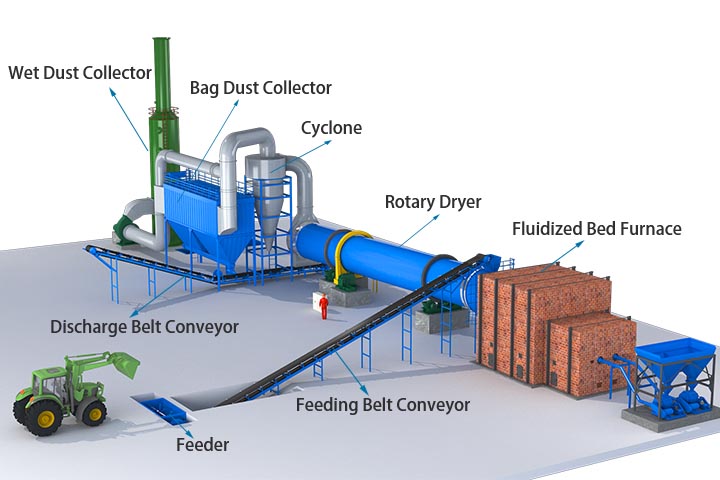

Clay Dryer Working Principle

Firstly, wet material is crushed by the crushing machine, then transported to the rotary drum dryer by the belt conveyor. Because of the inclination of drum dryer, material with hot air moves to the end of dryer body, during which process wet material gets fully contact with the hot air. After drying, most of the dry material is discharged through the belt conveyor. The left materials mixed with dust continue go into the cyclone dust collector and the bag dust collector in sequence, where the dust will be collected. Lastly, with the function of induced draft fan, the left material will discharged through the conveyor.

Rotary Dryer Running Video

Features of Clay Dryer Machine

1. Large processing capacity, less fuel consumption, low drying costs.

2. Downstream drying mode, hot air and wet materials are from the same side into the dryer, obtaining a high evaporation intensity and high thermal efficiency.

3. New feed and discharge device, eliminating the feeding blockage, discontinuous, uneven and recharge, reducing the load of dust removal system.

4. New internal structure, eliminating the adhesion phenomenon of the inner wall.

5. Wide application. The system is mainly suitable for materials with high water content, fine granularity and large viscosity.

6. A variety of heat sources are available, such as: diesel, natural gas, rice husk,etc.

7. According to the requirements of customers, the product size and moisture can be controlled. After drying, the moisture of clay can be ≤7%, and the particle size can be controlled below 8mm.

Rotary Drum Dryer in Factory

Custom Visit

Rotary Dryer Projects

Specifications

|

Specification |

Capacity |

Initial Moisture |

Final Moisture |

Total Power |

Floor Area |

| DDMG1918 |

300±10 |

25±5 |

≤5 |

109 |

7m*25m |

|

DDMG2218 |

500±30 |

25±5 |

≤5 |

128 |

8m*30m |

|

DDMG2520 |

700±30 |

25±5 |

≤5 |

240 |

8m*30m |

|

DDMG2822 |

1000±30 |

25±5 |

≤5 |

400 |

8m*40m |

|

DDMG3024 |

1200±30 |

25±5 |

≤5 |

480 |

12m*50m |

|

DDMG3428 |

1500±30 |

25±5 |

≤5 |

600 |

12m*60m |

|

DDMG3830 |

1800±30 |

25±5 |

≤5 |

800 |

16m*70m |

|

DDMG4032 |

2000±30 |

25±5 |

≤5 |

1000 |

18m*70m |

|

DDMG4238 |

2500±30 |

25±5 |

≤5 |

1200 |

20m*80m |

Send Inquiry